|

Power Supply

|

|

15-30VDC/24VAC(1), 4W max, 160mA max.

|

| TG-REM |

Powered through CAT-5 cable, no separate power required.

|

| Wiring |

Conductor

|

14-24 AWG, Minimum 600V, 75°C

|

|

Terminal Torque

|

0.5 N-m

|

|

Analog Outputs

|

2 programmable outputs

|

0-10V (default), 0-5V, 1-5V, 4-20mA (menu selectable)

|

|

CO Output Scaling

|

0-200ppm (default), 0-1000ppm (menu selectable)

|

|

NO2 Output Scaling

|

0-10ppm (default), 0-30ppm (menu selectable)

|

|

CO2 Output Scaling

|

0-10,000ppm (default), 0-10,000 (menu selectable)

|

|

Propane/Methane / Hydrogen Output Scaling

|

0-50% LEL (default), 0-50% LEL (menu selectable)

|

|

Oxygen Output Scaling

|

0-25% Vol (default), 0-25% Vol (menu selectable)

|

|

Refrigerant Output Scaling

|

0-1000ppm (default), 0-1000ppm (menu selectable)

|

|

H2S Output Scaling

|

0-100ppm (default), 0-100ppm (menu selectable)

|

|

Ammonia NH3 Output Scaling

|

0-100ppm (default), 0-100ppm (menu selectable)

|

|

Temperature Output Scaling (optional)

|

-20° to 85°C

|

|

BACnet /Modbus

|

Protocol RS-485

|

BACnet MS/TP, Modbus RTU, Modbus ASCII

|

|

Baud Rates

|

9600, 19200, 38400, 57600, 76800, 115200

|

|

RS-485 Loading

|

1/4 unit

|

|

Fan Relay

|

Fan relay characteristics (Standard Version)

Fan relay characteristics (Fail-Open Version)

|

N.C. 1A@24/30VDC (50/60Hz) (no mains connection)

N.O. 1A@24/30VDC (50/60Hz) (no mains connection)

|

|

Alarm Relay

|

Alarm relay characteristics (Standard Version)

Alarm relay characteristics (Fail-Open Version)

|

N.C. 1A@24/30VDC (50/60Hz) (no mains conenction)

N.O. 1A@24/30VDC (50/60Hz) (no mains conenction)

|

|

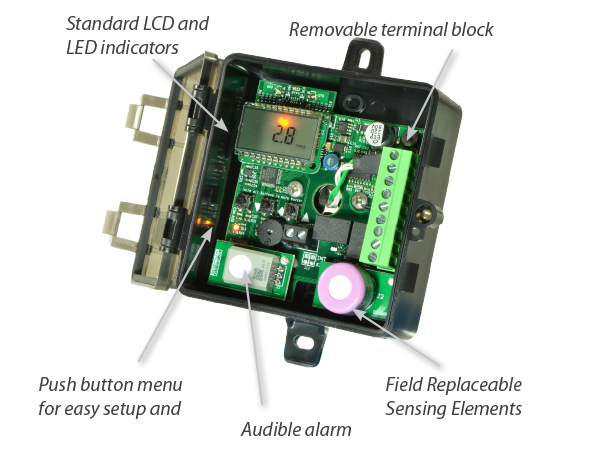

Display

|

3-1/2 digit LCD

|

Indicates CO ppm, NO2 ppm, Temp (menu selectable)

|

|

LEDs

|

Green, Yellow, Red

|

Green = Normal, Yellow = Relay, Red = Alarm

|

|

Audible Alarm

|

85dB Piezo transducer

|

30 minutes above alarm setpoint (menu selectable)

|

| CO Sensor Performance (4) |

Type

|

Electrochemical

|

|

Accuracy

|

±5% of Default Range, ±5% of Reading Above 200 ppm

|

|

Resolution

|

1 ppm

|

|

Certifications

|

UL2075 Recognized component

|

|

Life Expectancy

|

7 years

|

|

Recommended Calibration

|

Annual

|

|

Recommended Height and Coverage Area

|

3 to 6 feet, coverage 5000 to 7500 sq. ft.

|

|

NO2 Sensor Performance (5)

|

Type

|

Electrochemical

|

|

Accuracy

|

±5% of Default Range, ±5% of Reading Above 20 ppm

|

|

Resolution

|

0.1 ppm

|

|

Certifications

|

UL2075 Recognized component

|

|

Life Expectancy

|

7 years

|

|

Recommended Calibration

|

Annual

|

|

Recommended Height and Coverage Area

|

3 to 6 feet, coverage 5000 to 7500 sq. ft.

|

|

Oxygen Sensor Performance

|

Type

|

Electrochemical

|

|

Detection Range

|

0-25% Volume

|

|

Accuracy

|

±5% of range

|

|

Resolution

|

0.1%

|

|

Life expectancy

|

5 years, with Annual Calibration

|

|

Recommended Calibration

|

Annual

|

|

Recommended Height and Coverage Area

|

3 to 6 feet off the ground; coverage of 5000-7500 square feet

|

|

Ammonia Sensor (NH3) Performance

|

Type

|

Electrochemical

|

|

Accuracy

|

±5% of default range

|

|

Resolution

|

0.1 ppm

|

|

Life expectancy

|

5 years

|

|

Recommended Calibration

|

6 months

|

|

Recommended Height and Coverage Area

|

0.5 to 1 foot from ceiling; coverage 5000-7500 square feet (Click for details)

|

|

Carbon Dioxide (CO2)

|

Type

|

Non-Dispersive Infrared (NDIR)

|

|

Accuracy(6)

|

±(30ppm +3% of reading) (400-2000ppm), @-10-50°C

±(50ppm +5% of reading) Standard (2000-5000ppm), @-10-50°C

±(50ppm +3% of reading) Dual Channel (2000-5000ppm), @-10-50°C

±(100ppm +10% of reading) (5000-10000ppm), @0-50°C

|

|

Drift with ABC disabled (7)

|

35 ppm/month (8) (Standard), 5 ppm/month (8) (Dual Channel)

|

|

Range

|

0-2000/5000 ppm; Programmable up to 10,000 ppm

|

|

Resolution

|

1 ppm

|

|

Life expectancy

|

15 years

|

|

Response Time

|

30s |

|

Sample Response

|

1s

|

|

Recommended Height and Coverage Area

|

3 to 6 feet, coverage 5000-7500 square feet (Click for details)

|

|

Methane/Propane/Hydrogen

Sensors Performance

|

Type

|

Catalytic

|

|

Detection Range

|

0-50% LEL (Lower Explosive Limit)

|

|

Accuracy

|

5% of range

|

|

Certifications

|

UL2075 Recognized Component for Methane and Propane

|

|

Resolution

|

1%LEL

|

|

Ceritifications

|

UL2075 Recognized Component

|

|

Life expectancy

|

>5 years

|

|

Response Time

|

<10s to 90%

|

|

Recommended Calibration

|

Bump test annually, calibrate or replace if necessary. (9)

|

|

Long Term Stability Drift

|

Zero: <±2mV/year

Sensitivity: <±2mV/month

|

|

Recommended Height and Coverage Area

|

Methane/Hydrogen: Within 1 ft of ceiling

Propane: 1-3 ft above finished floor;

Coverage: Methane/Hydrogen 5000-7500 sq ft;

Propane 5000 sq ft (Click for details)

|

|

Hydrogen Sulphide (H2S) Sensor Performance

|

Type |

Electrochemical |

| Detection Range |

0-100 ppm |

| Accuracy |

±5% of Range |

| Resolution |

1 ppm |

| Life expectancy |

5 years with 6 month calibration |

| Recommended Calibration |

6 months |

| Recommended Height and Coverage Area |

3 to 6 foot above the ground; coverage of 5000-7500 square feet |

|

Refrigerant Sensors Performance

|

Type |

MOS |

| Detection Range |

0-1000 ppm |

| Resolution |

1 ppm |

| R22, R134A, R410A, R404A, R407c |

Calibrated for respective |

| R134A Sensitivity(7) |

@300ppm test gas: 450 ppm R410A, 425 ppm R407C, 400 ppm R404A, 370 ppm R22, 300 ppm R134A |

| Other Detectable Gases(8) |

R407A, R407F, R427A, R452B, R507, R448A, R454B, R455A, R455C, R422A, R422D, R452A, R514A, R32, Consult factory for other A2L gases |

| Life Expectancy |

10 years (typical expectation for MOS sensors) |

| Recommended Calibration |

6 months |

| Recommended Height |

6 inches above floor; no more than 18 inches above lowest level of equipment location for leak detection; coverage 5000-7500 sq ft. |

|

Operating Environment

|

Temperature, Operational()

|

-20 to 50oC (-4 to 122oF) (CO2 versions rated to -40oC)

|

|

Humidity

|

15-95% continuous, 0-95% intermittent

|

|

Max Elevation

|

2000m

|

|

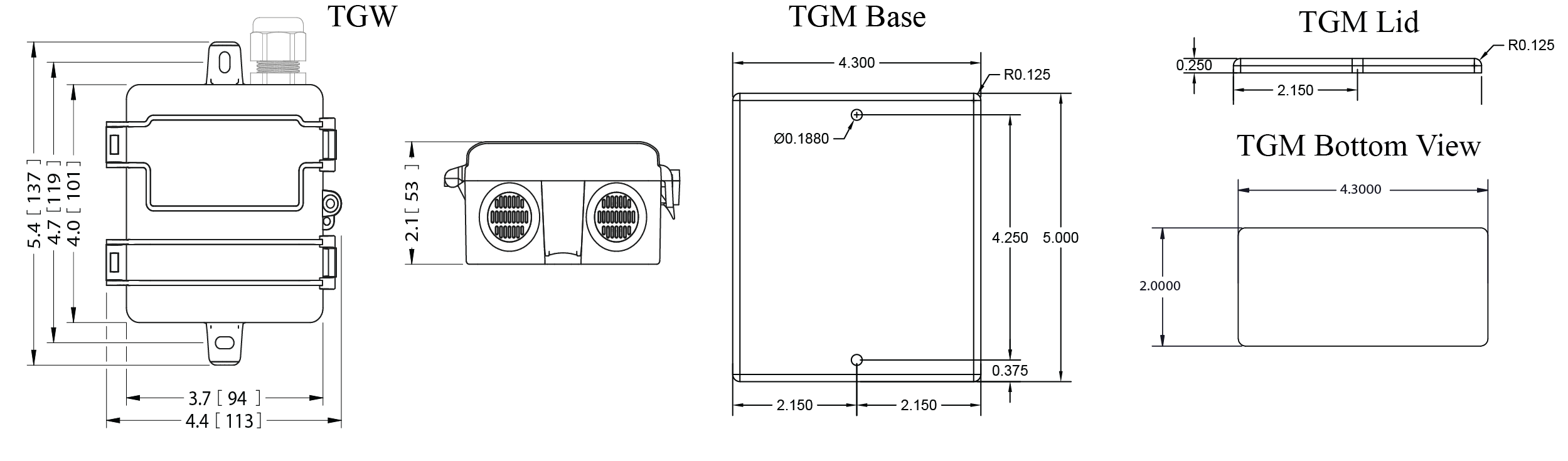

Enclosure

(Wall & Duct)

|

Material

|

ABS/Polycarbonate

|

|

Dimensions

|

4.0”h x 4.4”w x 2.1”d

|

|

Conduit Opening

|

Tapped 1/2” NPT

|

|

Rating

|

IP43 or NEMA 3R

|

|

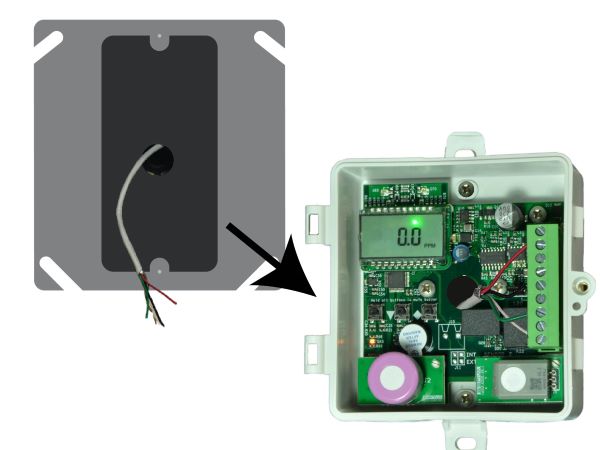

Enclosure

(Metal)

|

Material & Enclosure Rating

|

Powder-coated steel/acrylic

|

|

Dimensions

|

5.0”h x 4.3”w x 2.25”d

|

|

Opening

|

Dual air vents on bottom of enclosure

|

|

Mounting

|

Pre-drilled for 2x4” electrical box

|

|

Rating

|

IP41 or NEMA 3R

|

|

Agency

|

Compliance

|

UL61010-1 Listed UL, cUL, CE, UL 2075 Recognized Propane/Methane/Hydrogen/Nitrogen Dioxide/Carbon Monoxide sensor

|

|

(1) One side of transformer secondary is connected to signal common. Dedicated transformer is recommended. No mains circuit connection allowed. In addition, it is required to use an isolated power supply that is certified by a national or international standard (i.e. UL). Use of a Class 2 LPS power supply or greater is required.

(2) R134A sensor is factory calibrated to R134A gas but may be used as a general-purpose refrigerant sensor. Sensitivity to some other gases can be found in the installation manual. Actual response may vary depending on installation. For more accurate response to a specific gas, a unit may be field calibrated.

(3) These gases may be detected by the sensor but sensitivity curves are not available at this time.

(4) Carbon Monoxide full scale is 1000 ppm.

(5) Nitrogen Dioxide full scale is 30 ppm.

(6) CO2 sensor is equipped with a heater to account for temperatures down to -40°C.

(7) It is not recommended to de-activate ABC (auto-calibration) except for continuously occupied spaces or greenhouses. Drift ratings may vary based on environment.

(8) Combination CO/Methane, CO/Propane, or CO/Refrigerant sensors should be mounted according to Propane/Methane/Refrigerant recommendations. Consult factory for other combinations. Mounting height recommendations may be adjusted according to installation. Ensure sensor is accessible for maintenance and target gas has unobstructed access to sensor. Mount in accordance with ANSI/NFPA 70 and NEC or CEC.

(9) A bump test involves exposing the sensor to a reference gas and detecting the sensor’s response. If sensor response is out of accuracy range, recalibration or replacement of the sensor element may be necessary.

|